-

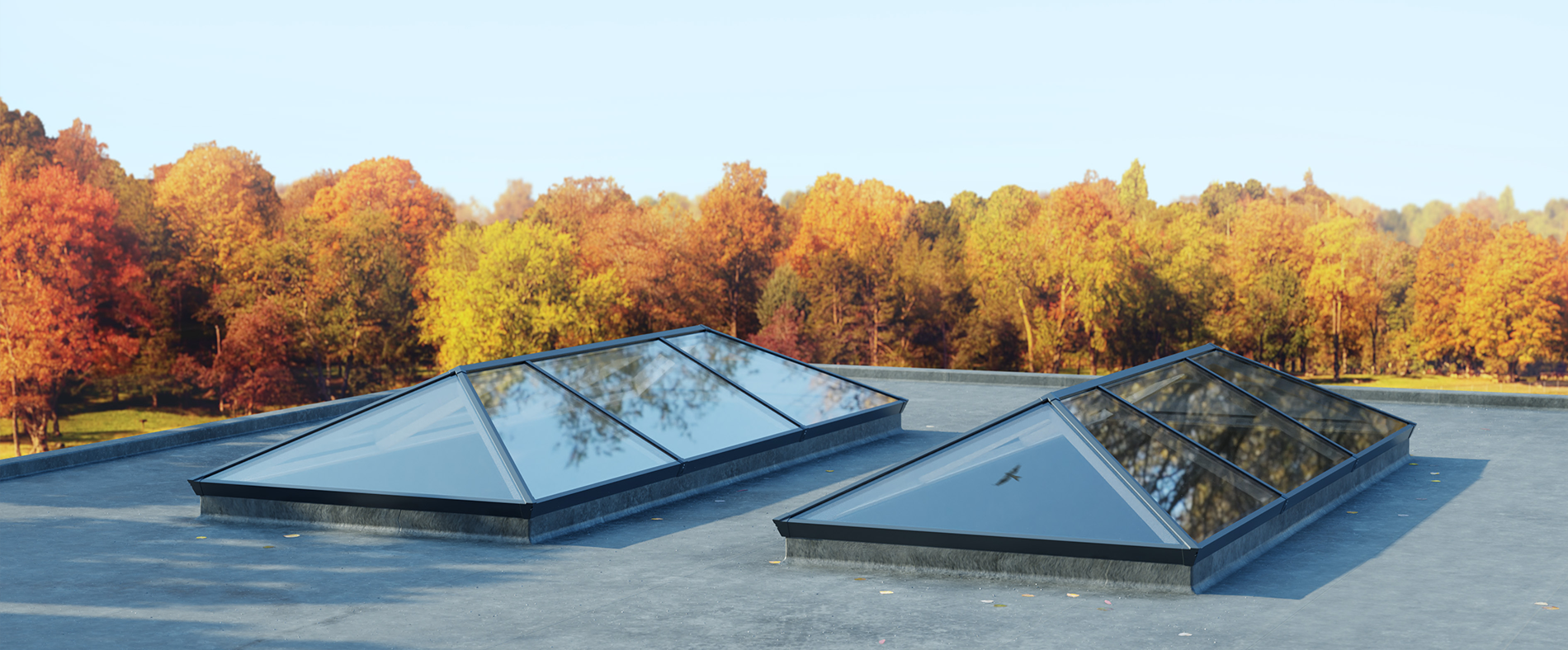

Windows & Doors

-

Roofs & Extensions

-

Security Hardware

-

Building Products

1

/

of

4

Levo Systems

Specialist trade suppliers and manufacturers of windows, doors and roofs.

We are based in the Midlands and deliver nationwide throughout the UK.

We hope you enjoy our website, it ha been developed to be educational, technical, informative and easy to use.

Don't forget to view the Video & Downloads sections.

Please contact us with any questions.

Contact Us

-

Email

Our team is here and ready to help.

-

Call

Please call us.

-

Opening Hours

Customer Service.

Monday - Friday: 8am - 4.30pm.